Locate our Johnson Tiles Display Centre in India

Visit our House of Johnson Showrooms or you can Book a Free Appoinment with our Tile Expert

Introduction to

Johnson Endura, the industrial tiling solution provider has looked into a very niche but highly important areas, which are sensitive to static electricity.

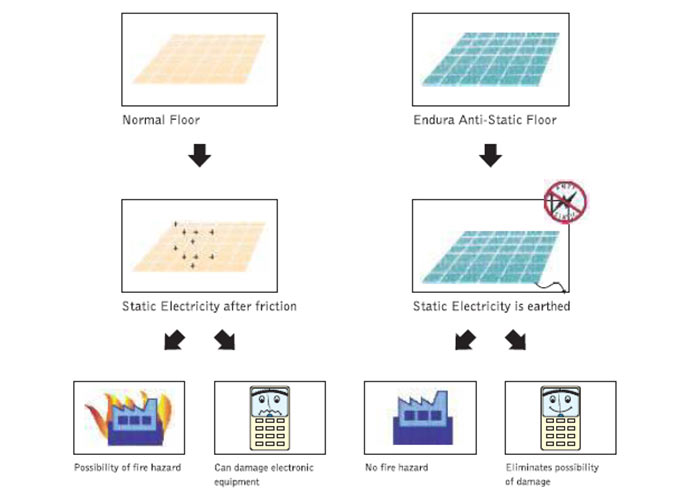

Anti-static dissipative type (Surface resistance between 1 Mega Ohm to 1 Giga Ohm) static electricity accumulates on the surface of any floor be it natural stone, ceramic tile or any other flooring material. This static electricity is accumulated due to the friction between any two surfaces like shoes and the floor. This static electricity could lead to sparks which could lead to fire hazards in areas like petrochemical industries, shell making factories, ordnance factories, defence industries, chemical plants, bulk drug plants, and other fire-prone areas. Johnson Endura Anti-static tiles remove the static electricity charge from the surface of the tile and earth it due to which the fire hazard is minimized.

Anti-static Conductive Type: (Surface resistance below 1 Mega Ohm) Anti-static tiles are also used for server rooms, computer rooms & electronic equipment rooms where static electricity can damage the working of electronic equipment.

Server Rooms, Petrochemical Factories, Ordnance Factories, Chemical Plants, Bulk Drug Plants, Fire-Prone Areas, Computer Rooms, Electronic Equipment Rooms, PLC Panel Rooms, PCB Manufacturing, IT Industry, Sophisticated Equipment Laboratories, Shell Making Factories, Defence Factories, Hospital Operation Theatres.

Surface Electrical Resistance - Conductive >1 Mega Ohm & Dissipative - 1 Mega Ohm to 1 Gig a Ohm

Static decay Time - Conductive - >0.5 sec Dissipative - >0.5 sec

Firm & Effective Grounding of Floors

60cm X 60cm Matt finish As Blue Tile

Stain Resistance

Endure Anti-Static Tiles Patented Product

Surface electrical resistance being the property of material decides the nature of the product in terms of its charge conductance. Surface Electrical resistance as per ANSI norms ensures a smooth transfer of accumulated static charge to the grounding path.

Static decay time as per ANSI norms ensures smooth discharge of accumulated static electricity from the surface.

Vitrified anti-static tiles help provide firm and permanent grounding.

Bigger size offers lesser joints. Matt finish with elegant anti-skid floor in blue shade.

Provides sufficient stain resistance property to effectively maintain the matt finish floor.

Being a glazed vitrified tile, the tile is virtually stain proof.

In the ceramic tile industry, where all the products are insulators, Johnson Tiles have developed a special patented product for their customers to address the specific concerns on ESD hazard.

Static hazard-free area resulting in smooth uninterrupted functioning of critical equipment. It helps in mitigating fire hazards from the floor due to static charges.

Compliance with the critical requirement of such sensitive areas. Static Hazard free area resulting in smooth uninterrupted functioning of critical equipment. Helps in mitigating fire hazards from floors due to static charges.

Assures Anti-Static property throughout the service life of product.

The customer is benefitted by a safe floor to meet industrial safety norms along with excellent aesthetic ambience.

Helps in maintaining good housekeeping norms.

The customer is benefitted by the best and only product from the ceramic industry which not only offers protection from ESD hazards but also provides excellent service life due to its mechanical properties.

Visit our House of Johnson Showrooms or you can Book a Free Appoinment with our Tile Expert

Find the best and nearest Johnson Tiles Dealers at your Place and at your Convenience

Download H & R Johnson Wall and Tiles Catalogue PDF for Spaces like Bathroom, Kitchen, Elevation, Bedroom, Drawing Room, and Parking Area.